CNC machining has revolutionized manufacturing by offering precision and efficiency across various sectors. From aerospace to medical devices, industries are harnessing its capabilities to produce complex parts with minimal waste. Understanding which industries benefit most from CNC machining not only highlights its versatility but also reveals opportunities for businesses looking to improve production processes.

Overview Of CNC Machining

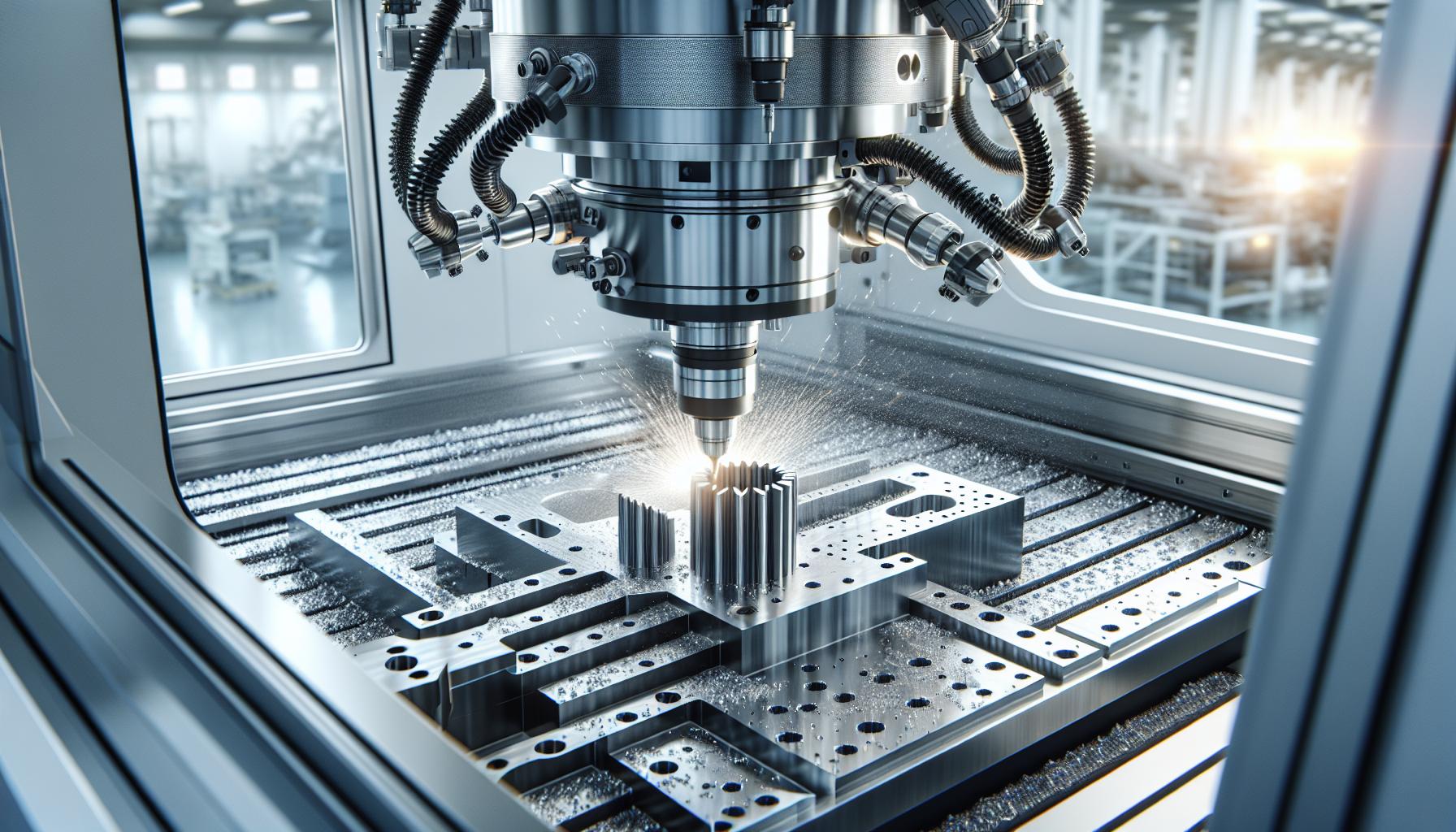

CNC machining, or Computer Numerical Control machining, employs computer-controlled tools to manufacture parts with high precision. This technology uses programmed commands to automate machines, significantly enhancing productivity and accuracy in manufacturing processes.

CNC machining accommodates a wide range of materials, including metals, plastics, and composites. The flexibility of this technology enables it to produce complex shapes and intricate designs that traditional machining methods struggle to achieve. Industries increasingly utilize CNC machining for prototypes and large-scale production runs, benefiting from its repeatability and minimal waste generation.

CNC machines incorporate various tools, such as lathes, mills, and routers, for specific applications. These machines handle tasks from cutting and drilling to engraving and milling, allowing for diverse functionalities tailored to specific industry needs. Integration with CAD (Computer-Aided Design) software streamlines the design and manufacturing processes, ensuring precise output aligned with client specifications.

The primary advantages of CNC machining include speed, precision, and consistency. Manufacturers can quickly produce parts with tight tolerances, making CNC machining a preferred choice for industries where quality control is critical. By adopting this technology, businesses experience reduced lead times and improved operational efficiency, consistently meeting customer demands.

Key Benefits Of CNC Machining

CNC machining offers significant advantages that improve manufacturing processes across multiple sectors.

Precision And Accuracy

CNC machining excels in producing components with extreme precision and accuracy. The use of computer-controlled tools ensures that each part meets exact specifications, reducing errors during production. Industries such as aerospace and medical devices rely on this high level of precision to meet stringent regulatory standards. For example, a deviation of even a fraction of a millimeter can lead to significant failures in critical applications. CNC machines consistently achieve tolerances within ±0.005 inches or better, ensuring reliable performance.

Increased Efficiency

CNC machining significantly increases production efficiency. Automated processes reduce manual intervention, cutting down on labor hours and minimizing human error. Production cycles often shorten due to rapid tool changes and the ability to run machines continuously. This efficiency enables manufacturers to produce complex parts quickly, accommodating both prototypes and large production runs. For instance, a CNC machine can produce hundreds of identical components in a fraction of the time it takes traditional methods, ultimately leading to lower production costs and faster time-to-market.

Industries That Benefit From CNC Machining

CNC machining plays a pivotal role across multiple industries, enhancing efficiency and precision in manufacturing. Businesses use this technology to streamline production and improve consistency.

Aerospace Industry

CNC machining is essential in the aerospace industry due to its requirement for precision. Components such as brackets, housings, and turbine blades must meet strict safety and performance standards. The ability to produce lightweight, durable parts from materials like titanium and aluminum makes CNC machining a preferred choice.

Automotive Industry

CNC machining significantly impacts the automotive industry by facilitating the mass production of components. Parts including engine blocks, transmission housings, and custom brackets benefit from the precise tolerances achievable through CNC processes. Increased automation reduces human error, ensuring high-quality components that adhere to stringent safety regulations.

Medical Device Manufacturing

The medical device manufacturing industry relies heavily on CNC machining for producing instruments and devices that require high precision. Items like surgical instruments, implants, and prosthetics demand exact specifications, which CNC machining provides. Its ability to work with biocompatible materials enables the production of safe, effective medical devices.

Electronics Industry

CNC machining supports the electronics industry by fabricating components that require intricate designs and excellent tolerances. Essential parts like circuit boards, enclosures, and connectors benefit from the efficiency and repeatability of CNC production. This technology allows rapid prototyping and production of complex electronic devices.

Furniture And Woodworking

In the furniture and woodworking sector, CNC machining enables the efficient production of custom designs. Manufacturing processes for items like cabinets, tables, and intricate wood carvings become streamlined. CNC machines allow for intricate cuts and shapes that improve the aesthetic appeal while ensuring precise dimensions for assembly.

Future Trends In CNC Machining

CNC machining continues to evolve, driven by technological advancements and market demands. Increased automation emerges as a vital trend, enhancing efficiency and reducing human error in the manufacturing process. Industries adopt automated setups to streamline operations and maximize productivity.

Artificial intelligence (AI) integration facilitates smarter machining systems. AI algorithms optimize tool paths and production schedules, allowing machines to adapt to changing operational conditions. These advancements improve precision and reduce waste, leading to lower operational costs.

Additive manufacturing, or 3D printing technology, complements CNC machining. Combining these methodologies allows manufacturers to create complex parts that integrate both subtractive and additive processes. This trend fosters innovation in product design and material usage.

Sustainability remains a key focus. CNC machining processes that incorporate eco-friendly materials and energy-efficient operations are gaining traction. Manufacturers prioritize sustainability to meet regulatory requirements and consumer demand for environmentally responsible practices.

Data analytics is increasingly utilized to monitor machine performance and production efficiency. Real-time data collection and analysis empower manufacturers to make informed decisions, predict maintenance needs, and optimize workflow.

Cybersecurity is becoming essential as CNC machines connect to the Internet of Things (IoT). Protecting sensitive data and ensuring system integrity are crucial as more manufacturers adopt connected technologies.

Continuous training and upskilling of personnel are vital to keep pace with these advancements. Workers equipped with modern skills can operate complex CNC systems and use new technologies effectively.

These trends indicate a dynamic future for CNC machining, providing significant opportunities for innovation and growth across various sectors.

Conclusion

CNC machining remains a cornerstone of modern manufacturing, offering unparalleled precision and scalability. Industries like aerospace, automotive, and medical devices benefit immensely from its capabilities. As pioneers like Yijin Solution CNC machining integrate emerging technologies, the potential for innovation expands further, ensuring businesses can stay competitive in a dynamic global market. By adopting CNC machining, companies can enhance production efficiency, maintain quality standards, and embrace a future of limitless possibilities.

Frequently Asked Questions

What is CNC machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computer-controlled tools to create precise parts. This technique allows for high accuracy and the production of complex shapes from various materials, making it suitable for different industries.

How does CNC machining improve manufacturing efficiency?

CNC machining enhances manufacturing efficiency by automating processes, reducing manual labor, and ensuring consistency in production. This leads to shorter production cycles, lower waste, and the ability to produce high-quality parts quickly.

Which industries benefit the most from CNC machining?

Industries like aerospace, automotive, medical devices, electronics, and furniture benefit significantly from CNC machining due to its precision and capacity for mass production. Each sector utilizes CNC technology to improve product quality and efficiency.

What are the primary advantages of CNC machining?

The main advantages of CNC machining include speed, precision, and consistency. These benefits result in reduced lead times, lower production costs, and high-quality output crucial for industries with strict regulatory standards.

How does CAD software integrate with CNC machining?

CAD (Computer-Aided Design) software streamlines the design process for CNC machining. It allows engineers to create 3D models that can be directly used by CNC machines, improving accuracy and efficiency in manufacturing.

What future trends are expected in CNC machining?

Future trends in CNC machining include increased automation, AI integration for optimizing production, a focus on sustainability with eco-friendly practices, and the use of data analytics for performance monitoring. Continuous training will also be essential for adapting to these advancements.